4 or 5 years ago I built a .416 Rigby rifle for a client, and that rifle was based on a vintage Rigby model #5 rifle. Basically it had many of the features of the vintage Rigby’s, such as the barrel contour, single square magnum action and overall look, but stocked to the customers dimensions and with a cheek piece. I had sent pictures of it to another great client of mine and we decided to build a rifle with the same features of the Buehler #5 in .416, but scaled down, and in the caliber .30-06.

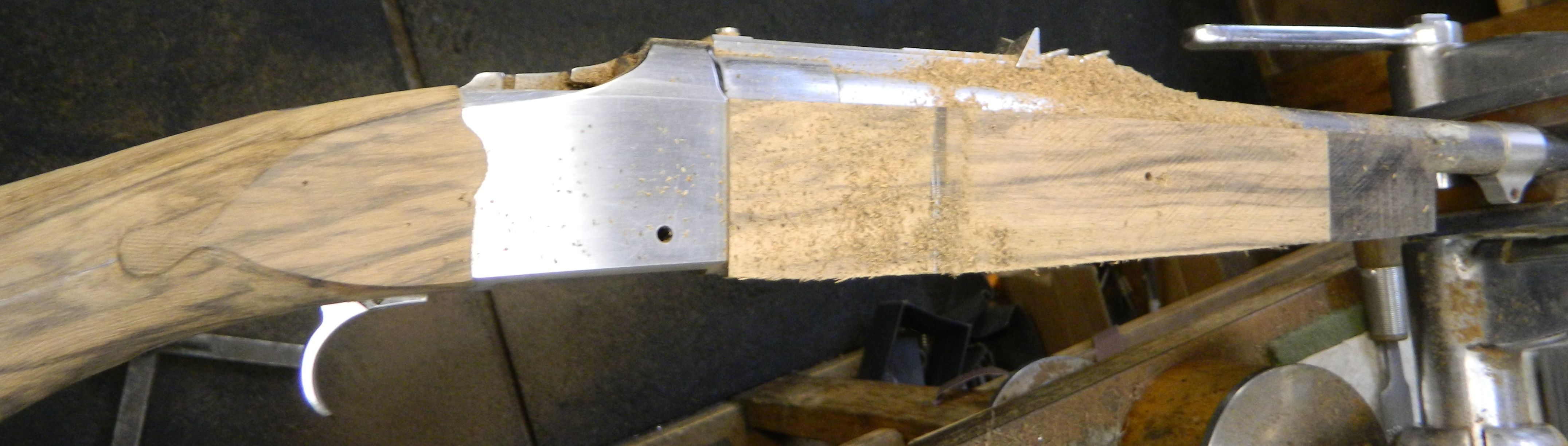

The action used on this rifle was made by Granite Mountain Arms and is a light weight, small ring 33/40 style square bridge action. I cut a thumb cut into the receiver to give it more of a vintage look. Rigby used on their #5 rifles two different barrel contours. The first was with a very heavy barrel, integral rib and stepped down at the sling swivel band. The second had a long, heavy shank with an integral sight rib, but was overall somewhat lighter. This is the contour we decided initially on the .416 Rigby and I used the same contour but much smaller on the .30-06. The barrel started off oversize and I machined the integral rib into it.

The banded and flush fit front sight ramp and the sling swivel band I machined from solid and soldered to the barrel.

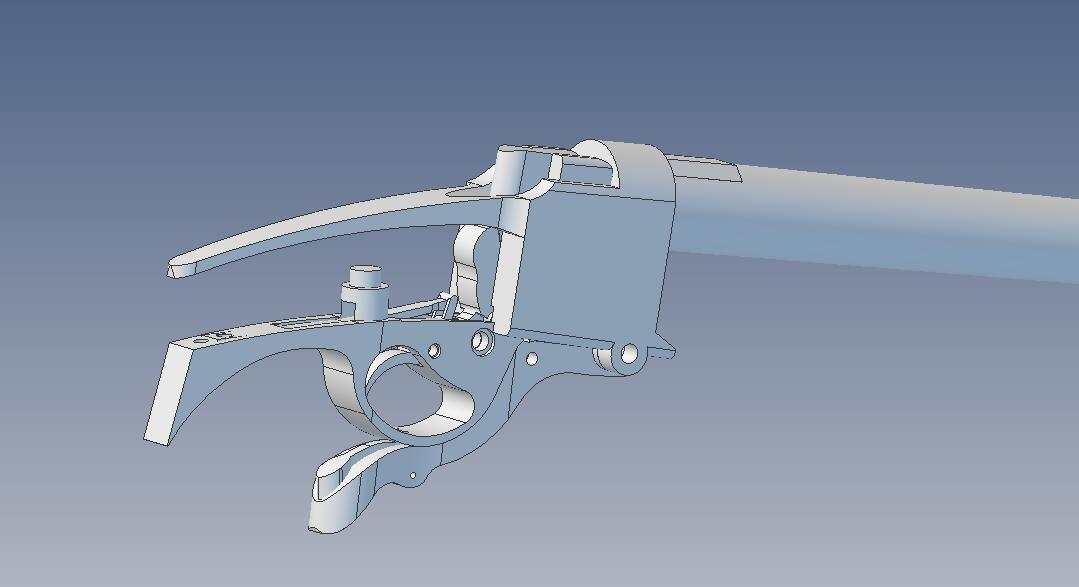

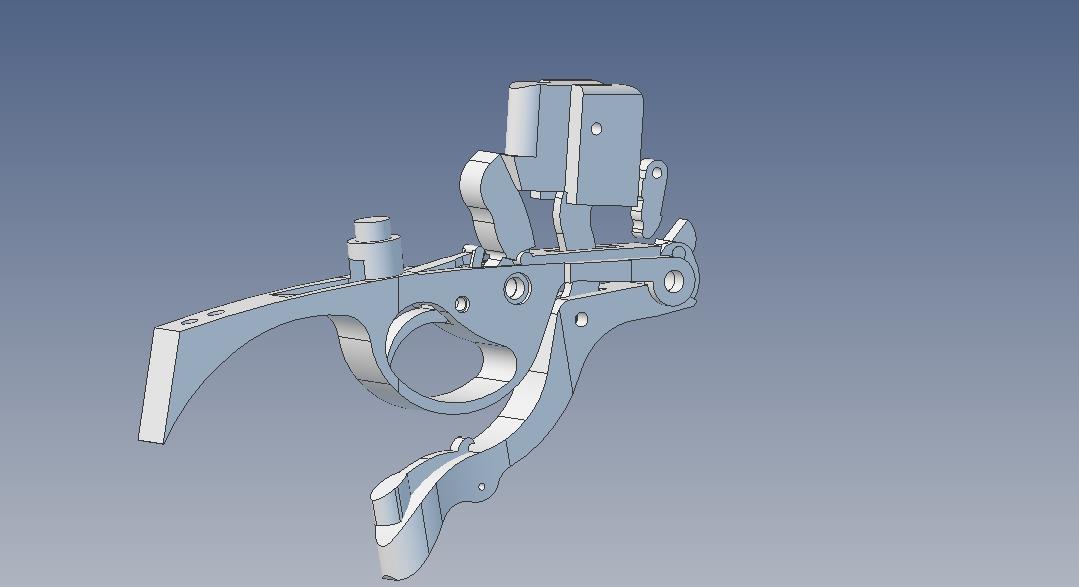

A Blackburn drop box magazine was added to the action and the rifle was stocked with a nice Turkish walnut blank. The scope mount on the rifle is my cam-lever mount and it is detachable with a 1/4 turn on each ring lever. This scope mount is especially well suited for square bridge actions, as the rifle still looks very clean with the scope removed.

The stock was made to the customers dimensions. After checkering and finishing the rifle was, as always, tested at the range for function and accuracy.

And here is the final result:

The combination of fine walnut and polished steel, made into a high precision instrument of beauty and style, yet capable of withstanding huge pressures and propelling a projectile faster then the speed of sound accurate into the center of a target, what’s not to love about it?

The combination of fine walnut and polished steel, made into a high precision instrument of beauty and style, yet capable of withstanding huge pressures and propelling a projectile faster then the speed of sound accurate into the center of a target, what’s not to love about it?