A good customer of mine recently mentioned that he had no idea how many of the parts on my custom rifles are being manufactured by me and where not purchased from suppliers. That made me think that perhaps I should post more often pictures of work in progress. The following pictures I took recently while working on the sight ramps of a rifle in the caliber .404 Jeffery.

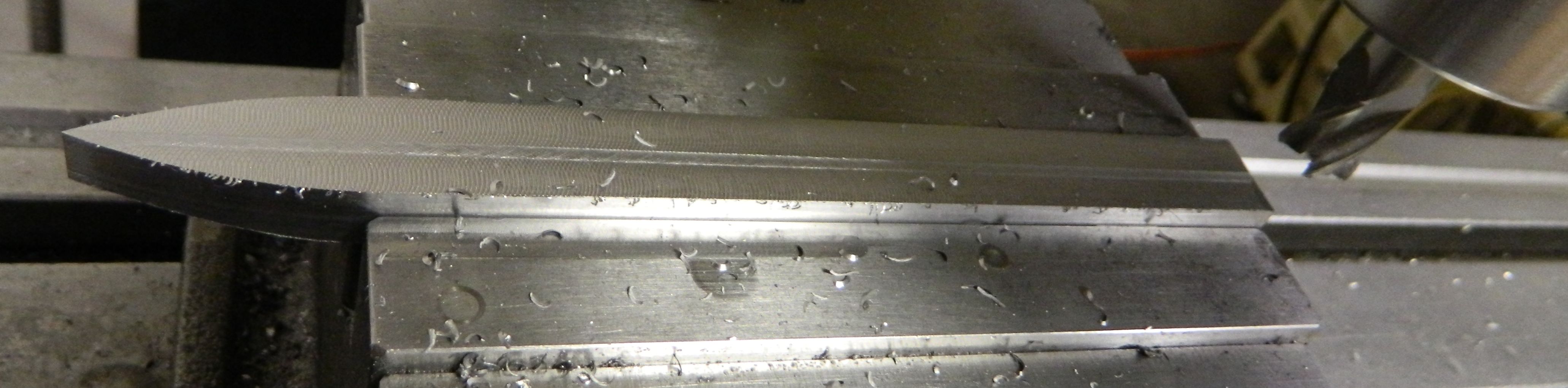

I’m starting with a picture of a quarter rib in process for a “Buehler English Express” rifle. First the rib is rough machined, then roughly hand-fitted to the barrel.

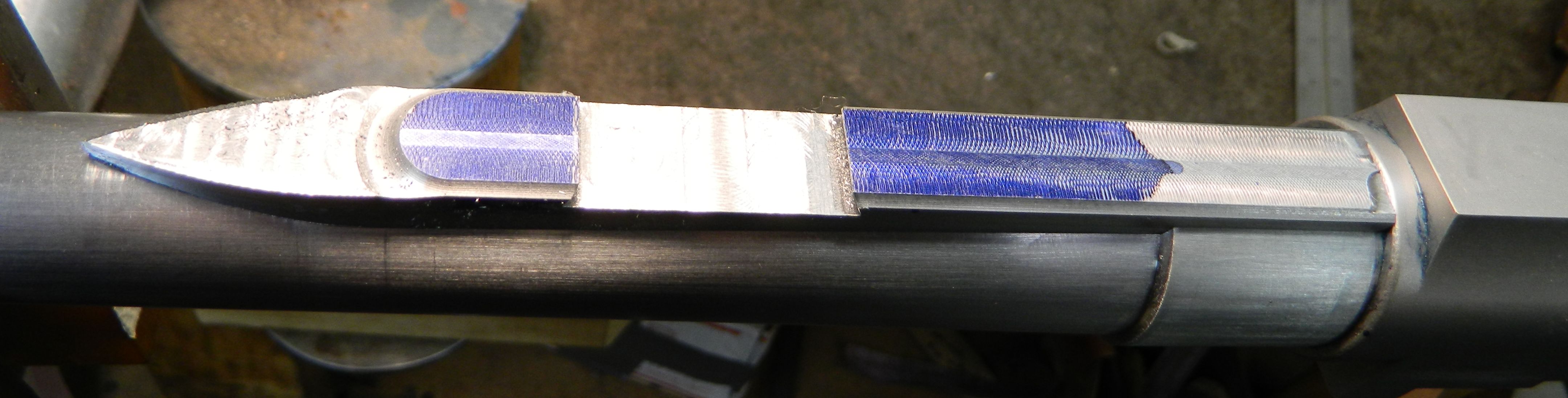

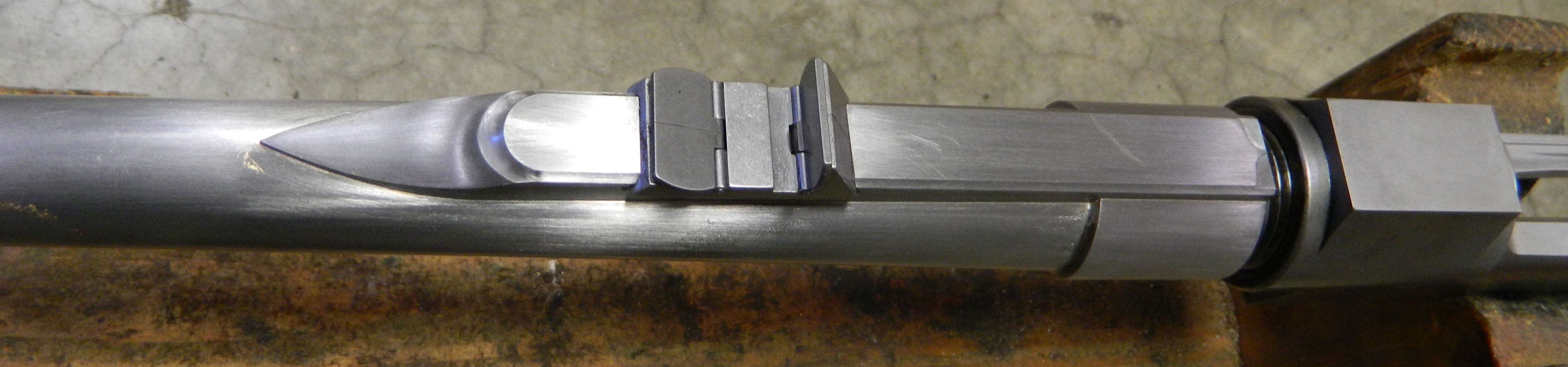

Then I machined the dovetail for the rear sight and profiled the rib further. The ribs slightly warp during the machining and require final hand-fitting. The goal is to achieve a great fit, so that the rib can be soldered onto the barrel without adding any stress to the barrel.

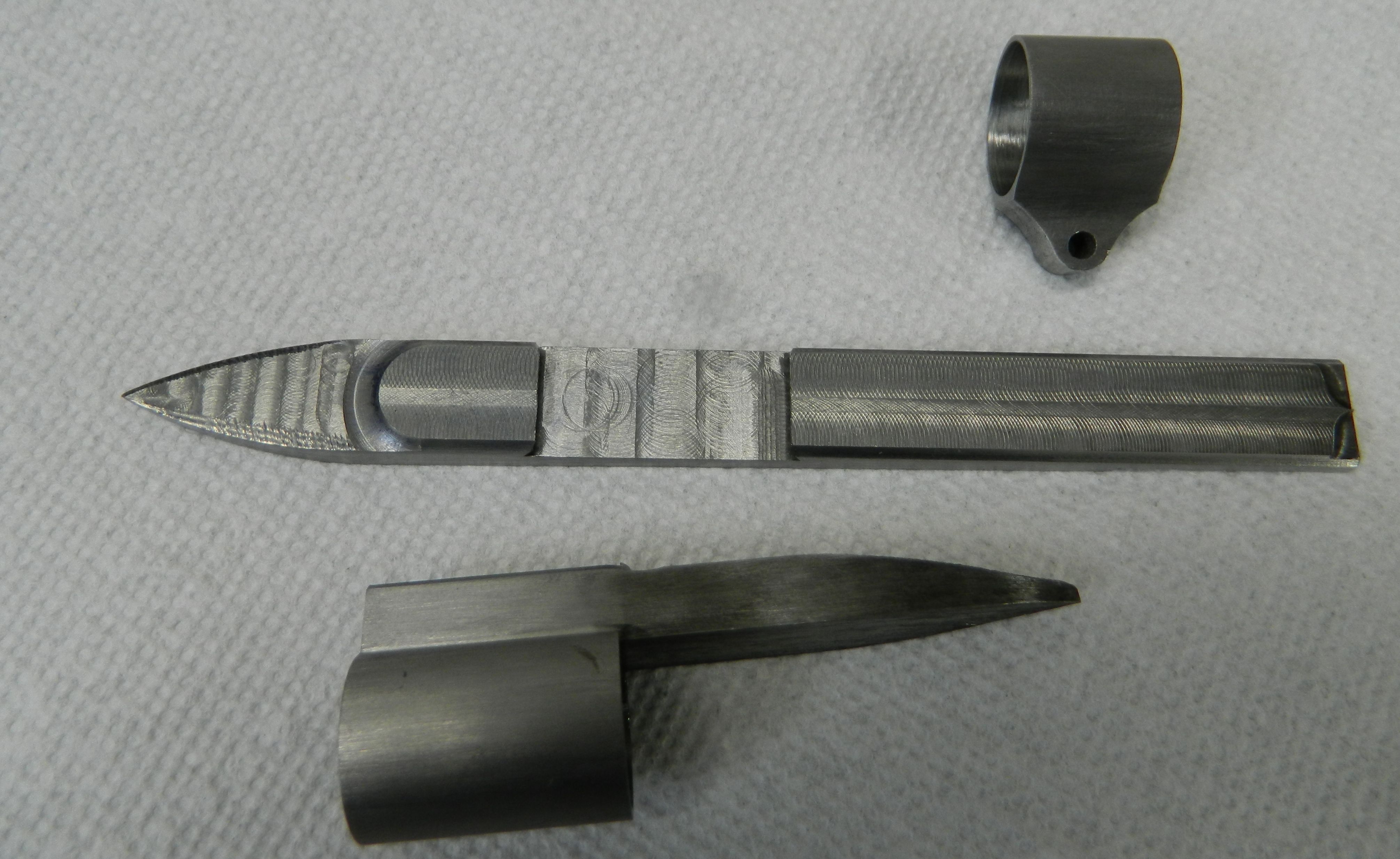

A barrel band and the front sight ramp are also fitted at this stage. These parts are also made here in the shop. The picture is of a custom machined front sight ramp, barrel band and the quarter rib, all ready for soldering.

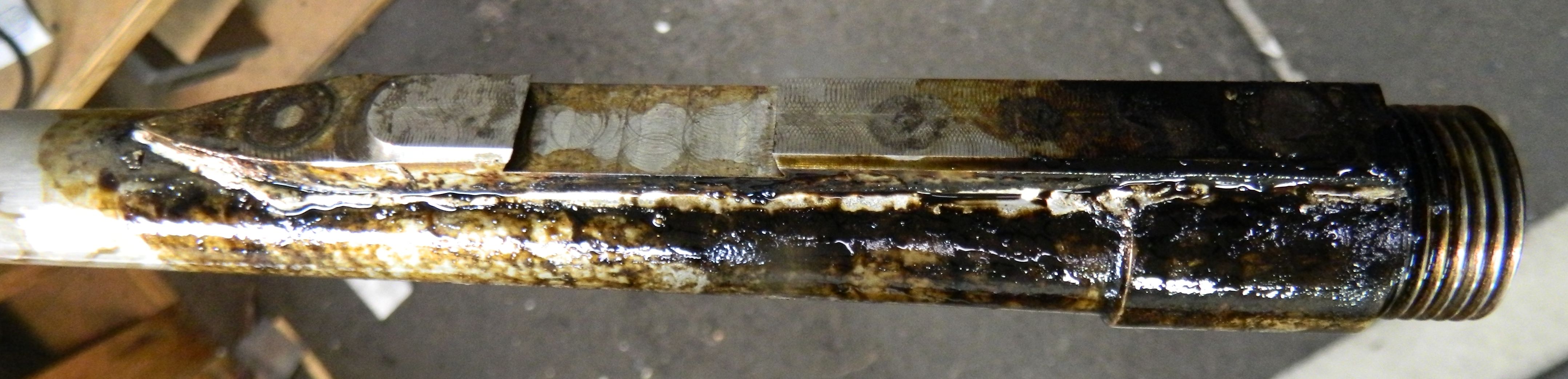

This picture was taken after soldering and before washing off of the solder flux. What a beautiful mess it is at this stage. As long as the parts are very well fitted and the soldering has been meticulously performed, the solder joints are incredibly strong and absorb shock very well. It will last for hundreds of years, as proven by so many old muzzle-loaders.

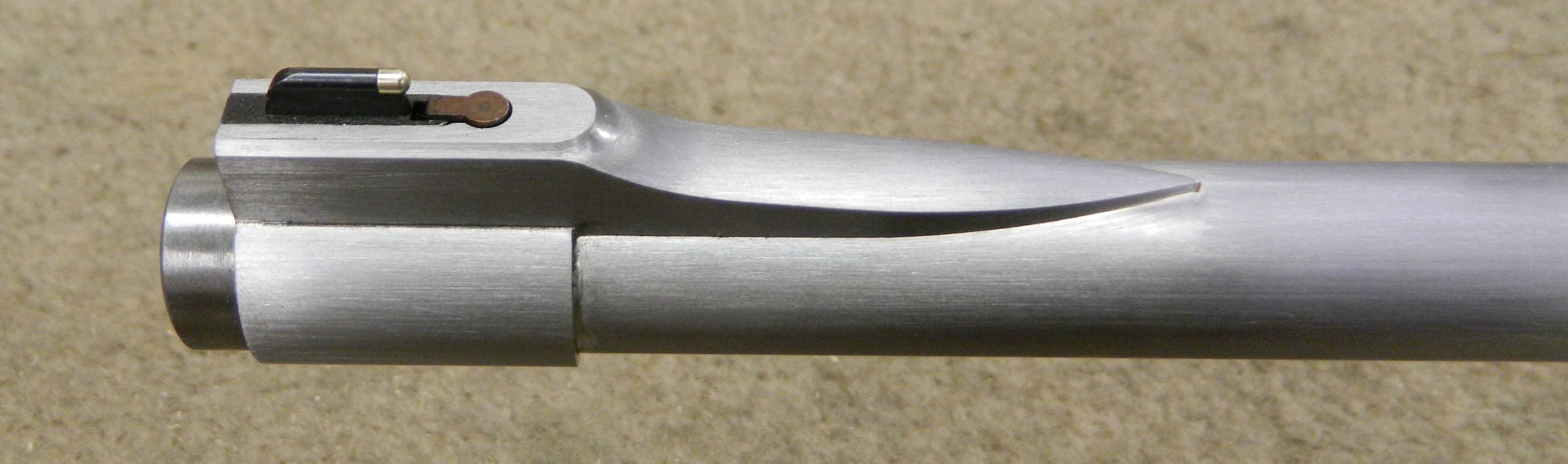

After the excess solder was removed, I then filed and polished the ramps to the final shapes and installed the sights.

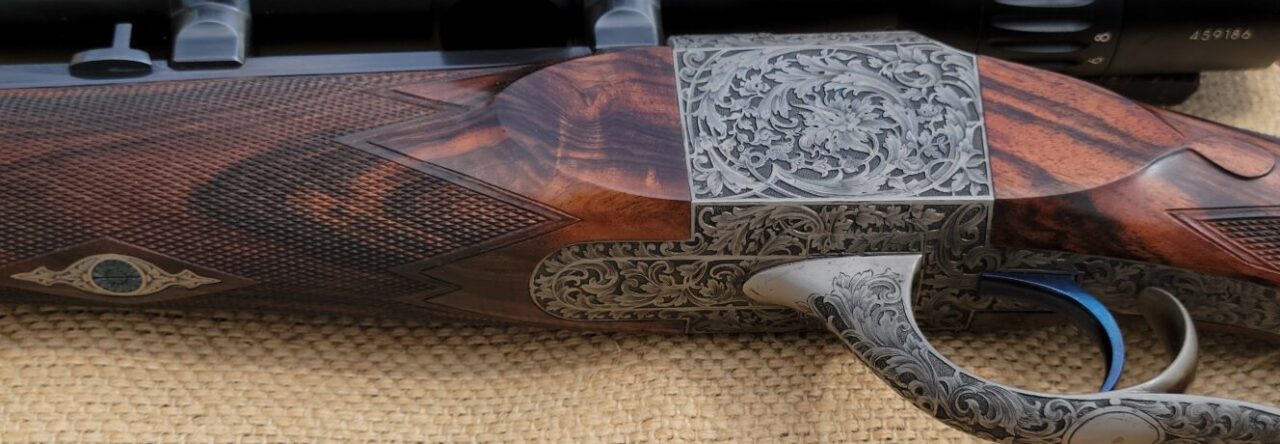

A lot of work, no doubt, but I hope you will agree that the outcome is worth it.